PRODUCT

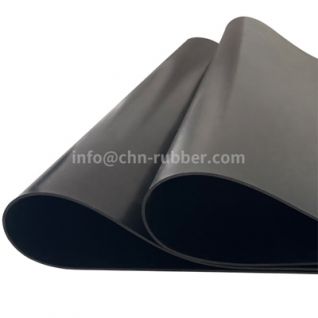

SBR 60±5 Shore A abrasion resistant rubber sheeting

Whatsapp & P.H: +8615222735180

Email: info@chn-rubber.com

1. Material: SBR rubber

2. Thickness:1mm-15mm

3. Width: 1m/1.2m/1.4m/1.5m/1.6m/1.8m/2.0m

4. Length: 10m/roll 20m/roll or as your request

5. Gravity: 1.4g/cm3

6. Hardness: 60±5Shore A

7. Tensile strength: 5-6Mpa

8. Elongation: 300%

SBR abrasion resistant rubber sheeting professional manufacturer

Abrasion resistant rubber sheeting data sheet:

| Thickness | Weight | Stardard |

| 1mm | 1.4KGS/M² | ASTM D397 |

| 1.5mm | 2.1KGS/M² | ASTM D2240 |

| 2mm | 2.8KGS/M² | ASTM D412 |

| 3mm | 4.2KGS/M² | ASTM D412 |

| 4mm | 5.6KGS/M² | |

| 5mm | 6KGS/M² | |

| 6mm | 8.4KGS/M² | |

| 8mm | 11.2KGS/M² | |

| 10mm | 14KGS/M² | |

| 12mm | 16.8KGS/M² | |

| 15mm | 21KGS/M² |

Description:

Abrasion resistant rubber sheeting is a versatile material that is designed to withstand the damaging effects of abrasion and wear. It is commonly used in various industrial applications where there is a high risk of mechanical impact, friction, and scraping. This type of rubber sheeting is composed of different types of rubber, including SBR, NR, and EPDM rubber. SBR (Styrene-butadiene rubber) is a synthetic rubber that offers excellent abrasion resistance, along with good tensile strength and resilience. NR (Natural Rubber) is a highly flexible and durable material known for its exceptional resistance to wear and tear. EPDM (Ethylene Propylene Diene Monomer) rubber is a synthetic rubber with excellent resistance to heat, weathering, and chemicals. Combined, these rubber materials create a strong and durable rubber sheet that can withstand harsh environments and extreme conditions. Abrasion resistant rubber sheeting is commonly used in applications such as conveyor belts, chute linings, gaskets, seals, and anti-vibration mats, providing reliable protection and longevity.

Image: