Rubber For Mining

- 1/1

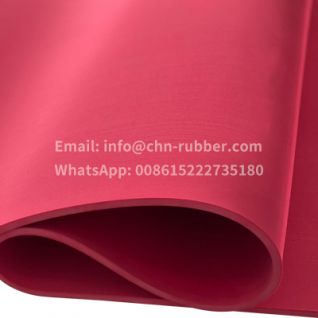

LIQUID-PHASE LATEX RUBBER SHEET

Liquid-phase method is an advanced processing method in rubber industry. This rubber sheet is 95% natural rubber, with super high tear and wear resistance, excellent elasticity, making it ideal for demanding industrial applications.

Tianjin China Rubber Co.,Ltd provides:

|

|

|

Liquid-phase Premium Rubber Feature:

- High Natural Rubber Content: Proprietary vulcanized natural rubber, made from high-quality, environmentally friendly latex, with enhanced elasticity and resilience.

- Advanced Liquid Compounding: Unique manufacturing process ensures consistent thickness and smooth surface.

- Superior Tensile Strength: Superior stretch and abrasion resistance over ordinary natural rubber sheets.

- Enhanced Tear and Abrasion Resistance: Withstands high impact and abrasive conditions with up to 800% elongation at break.

- Temperature Resilience: Performs well in temperatures ranging from -40 °C to +80 °C.

Application:

This rubber is particularly suitable for fine slurry applications and wet abrasive conditions. It can exert its greatest advantages in wet abrasive conditions.

Extensively used for wet abrasion resistance, particularly as a lining for pipes, hoses, and tanks involved in dewatering, desliming, and tailings processes.

Other Industry Uses: Heavy Duty Rubber Scrapers for Floor Washing Machines/Backing for Animal Recovery Rooms/Shooting Ranges.

Ultra High Wear-resistance Rubber Feature:

- addition to the high performance characteristics of liquid-phase premium rubber, also boasts a notable advantage with its high friction coefficient.

- Excellent wear resistance when handling fine particles and sticky materials, suitable for both dry and wet mining environments.

- Rubber products also made from natural latex rubber, 95% pure natural rubber.

We have independently developed high-quality adhesives to ensure that the performance of rubber products is well utilized during each use. The adhesive peeling strength (N/mm, 24h) is ≥8. The adhesive is mainly used for bonding rubber to rubber, rubber to metal, rubber to fabric, and fabric to fabric. It is used in conjunction with curing agent, metal surface treatment agent, rubber treatment agent and activator. It is an ideal adhesive for bonding various wear-resistant rubber sheet materials to metals.

Application:

Widely used in lining of vibrating screen beams, shields, feeders, mixing barrels, separators, mud tanks, pipes, flotation tanks, storage tanks and water tanks

How to choose rubber mining correctly?

It depends on various conditions such as mining conditions, material size, wear environment, impact angle, slurry concentration, temperature, etc.

Contact us for more information

Email: info@chn-rubber.com

WhatsApp: +8615222735180