PRODUCT

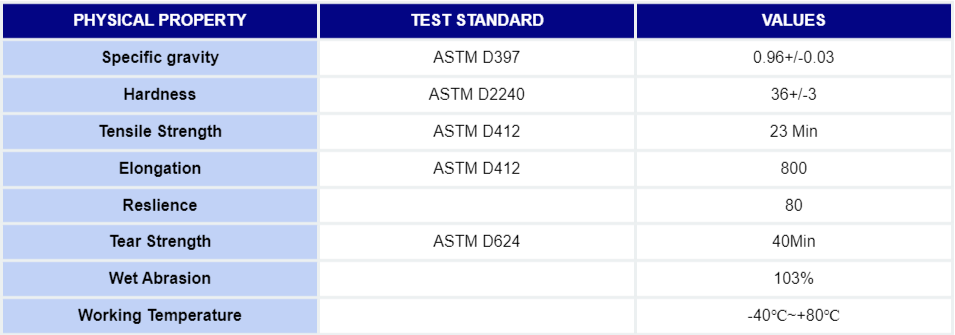

36Shore A 0.96 Specific gravity red color natural rubber sheet

Email: info@chn-rubber.com

WhatsApp: +8615222735180

The red color, common in such sheets, aids in visual identification, adds UV resistance, and signals specific performance attributes suitable for industrial settings.

Description:

Abrasion resistant rubber sheet parameter:

Key Characteristics of Liquid-Phase abrasion resistant rubber sheet

Uniform Thickness: Because the rubber starts as a liquid, it can spread evenly across a mold, ensuring consistent thickness and reducing material inconsistencies.

Surface Customization: The liquid-phase method allows for various surface finishes, such as smooth, polished, or textured (e.g., brushed or roughened surfaces), which can improve grip or abrasion resistance.

Complex Shapes and Sizes: Liquid rubber can be molded to fit specific designs and dimensions more easily than traditional rubber sheets, allowing for custom shapes or large, seamless sheets.

High Material Purity and Elasticity: Liquid-phase abrasion resistant rubber sheet, particularly those made with high percentages of natural rubber, often have excellent flexibility, resilience, and tensile strength, suitable for heavy-duty applications like mining, industrial machinery, and sealing gaskets.

Enhanced Durability: Additives can be mixed into the liquid rubber to boost UV resistance, chemical resistance, or color stability, improving the sheet’s performance in harsh or outdoor environments.

The liquid-phase method is especially favored in applications demanding precision, such as mining, construction, and heavy machinery, where durability and performance are critical.

Designed for use with rubber sheets, these adhesives deliver exceptional durability even in extreme conditions, like high abrasion, heat, and exposure to chemicals.

- Flexibility and Elasticity: Maintains flexibility to accommodate the natural expansion and contraction of rubber without cracking or losing adhesion.

- Fast-Curing and Easy Application: Offers quick drying and curing times, simplifying application and reducing downtime.

These adhesives are a result of our specialized research and testing, ensuring the performance and quality that aligns perfectly with the rubber sheets we manufacture, giving our customers a complete solution that lasts.