PRODUCT

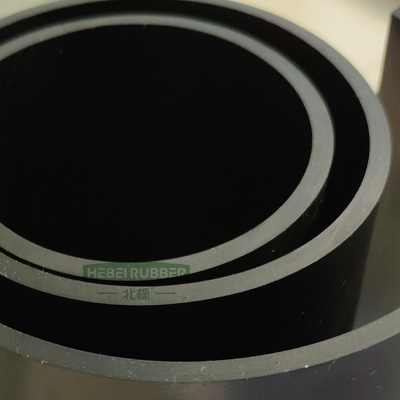

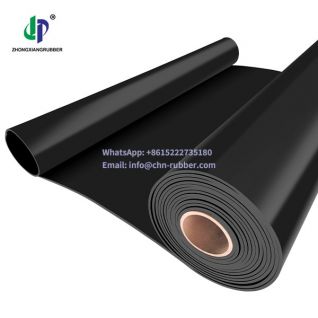

5mm Neoprene gasket roll CR rubber sheet

Whatsapp & P.H: 008615222735180

Email: info@chn-rubber.com

Material: : vulcanized rubber

Thickness: 1mm ~15mm

Width: 2.0m MAX

Gravity: 1.7g/cm3

Hardness: 75±5

Tensile strength: 2Mpa ~ 2.5Mpa

longation: 160%

About Neoprene Rubber Sheet:

Neoprene sheet, also known as neoprene sheet, is a versatile and durable material commonly used in a variety of industries. The synthetic rubber sheet is made through a complex process that involves the polymerization of chloroprene, a monomer derived from petroleum. Neoprene gasket roll have several advantageous properties that make them suitable for a wide range of applications. One of its key properties is its excellent resistance to oils and chemicals, allowing it to withstand exposure to a wide range of substances without degradation or deterioration.

This makes it ideal for industries such as automotive, oil and gas, and chemical processing. In addition, Neoprene gasket roll is highly elastic and have excellent physical properties, including good tensile strength and elongation. This enables it to withstand harsh working conditions such as extreme temperatures and high pressures. Its exceptional flexibility and stretchability also make it a popular material for gaskets, seals and vibration-damping components. Another notable feature of neoprene sheets is their resistance to weathering, ozone and UV radiation. This makes it suitable for outdoor applications where exposure to sunlight and other environmental factors needs to be considered.

It also has low compression set, which means it retains its original shape and size after being subjected to compressive forces for an extended period of time. In addition to its functional properties, neoprene gasket roll is available in a variety of thicknesses, colors and textures to suit specific requirements. It can be easily manufactured and molded into different shapes, making it an ideal material for custom machined parts and products. Overall, neoprene sheet is a highly versatile and reliable material with excellent resistance to oil, chemicals, weathering and physical stress. Its wide range of applications and properties make it a popular choice in industries where durability, flexibility and long-lasting performance are critical.

Neoprene gasket roll size:

| Thickness | Weight KGS/m² | Chemical Specifications | |

| 1mm | 1.7 | Aliphatic Hydrocarbons | POOR |

| 1.5mm | 2.55 | Aromatic Hydrocarbons | POOR |

| 2mm | 3.4 | Lubrcating Oils | POOR |

| 3mm | 5.1 | Outdoor Exposure | REGULAR |

| 4mm | 6.8 | Ozone Exposure | POOR |

| 5mm | 8.5 | Diluted Acids | REGULAR |

| 6mm | 10.2 | Diluted Alkali | REGULAR |

| 8mm | 13.6 | Vegitable Oil | POOR |

| 10mm | 17 | Animal Oil | POOR |

| 12mm | 20.4 | ||

| 15mm | 25.5 | ||