Rubber sheet

How thick should a Neoprene rubber sheet be for [specific application]

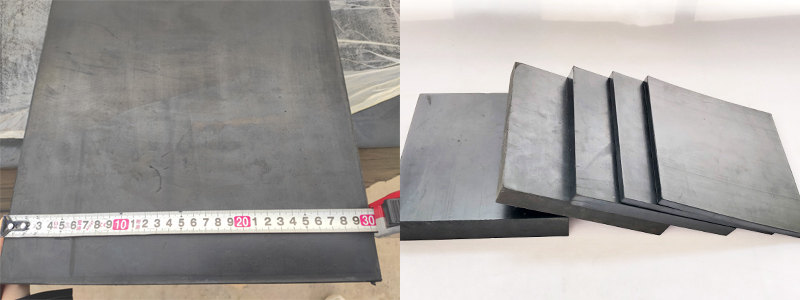

![How thick should a Neoprene rubber sheet be for [specific application]](/./Uploads/news/2024-03-18/en-neorepne-rubber1-162146.jpg)

Neoprene rubber sheets are versatile materials known for their flexibility, durability, and weather resistance. From wetsuits to industrial gaskets, these sheets find application across a wide range of industries. One crucial factor to consider when working with Neoprene rubber sheets is their thickness, as it directly impacts their performance in specific applications. In this article, we'll explore how to determine the ideal thickness of Neoprene rubber sheets for various uses.

Understanding Neoprene Rubber Sheet Thickness:

Neoprene rubber sheets are available in a variety of thicknesses, typically ranging from 1.5mm to 50mm. Each thickness offers unique properties and is suitable for different applications based on factors such as flexibility, insulation, and impact resistance.

1.5mm to 6mm Neoprene Sheets:

Neoprene sheets in the 1.5mm to 6mm range are considered thin to medium thicknesses and are commonly used in applications where flexibility and insulation are essential. For instance, in the manufacturing of wetsuits and drysuits for water sports enthusiasts, thinner Neoprene sheets provide the necessary warmth and protection while allowing for ease of movement. Additionally, these thicknesses are ideal for producing gaskets and seals in various industries due to their ability to conform to irregular surfaces and provide a reliable seal.

40mm and 50mm Neoprene Sheets:

In contrast, thicker Neoprene sheets, such as those measuring 40mm and 50mm, are utilized in applications requiring enhanced cushioning, impact resistance, and vibration dampening. Industries such as automotive, construction, and marine engineering rely on these thicker sheets for applications such as padding in machinery, shock-absorbing components, and marine fender systems. Their increased thickness provides superior protection against impact, abrasion, and harsh environmental conditions, making them indispensable in demanding industrial environments.

Determining the Ideal Thickness for Specific Applications:

When determining the ideal thickness of Neoprene rubber sheets for a specific application, several factors must be considered:

Functional Requirements: Identify the functional requirements of the application, such as insulation, impact resistance, or sealing properties.

Environmental Conditions: Consider the environmental conditions the Neoprene sheets will be exposed to, including temperature fluctuations, moisture levels, and chemical exposure.

Flexibility vs. Thickness: Balance the need for flexibility with the desired thickness. Thinner sheets offer greater flexibility but may sacrifice some insulation or impact resistance compared to thicker sheets.

Industry Standards and Regulations: Consult industry standards and regulations relevant to the application to ensure compliance and safety.

By carefully assessing these factors and selecting the appropriate thickness of Neoprene rubber sheets, manufacturers and end-users can optimize performance, durability, and safety in various applications.

Conclusion:

Choosing the right thickness of Neoprene rubber sheets is crucial for ensuring optimal performance and longevity in specific applications. Whether for wetsuits, gaskets, or industrial padding, understanding the unique properties of different thicknesses allows for informed decision-making and superior results. By considering functional requirements, environmental factors, and industry standards, individuals and businesses can confidently select Neoprene rubber sheets that meet their specific needs with precision and reliability.

Kathery Cui:

Whatsapp: 008615222735180

P.H: +8615222735180

Email: info@chn-rubber.com

Wechat: 008615222735180

Address: Business center industry parking , yan'an Road , Nankai district, Tianjin , China.

Tianjin China Rubber Co., Ltd