Rubber sheet

Everything You Need to Know About Anti Static Mat: FAQs and Professional Answers

We've rounded up the most frequently asked anti static mat (ESD) questions on Google:

What is an anti static rubber mat?

An anti-static rubber mat is a type of rubber material that is designed to prevent static electricity buildup on surfaces. These rubber sheets are commonly used in applications where static electricity poses a risk to sensitive electronic components or equipment.

How does an anti static rubber mat work?

Anti-static rubber sheets work by containing conductive particles or fibers within the rubber material, which help to dissipate static charges on the surface of the rubber. The conductive particles or fibers create a conductive path that allows static electricity to flow safely away from the surface of the rubber, preventing buildup and reducing the risk of damage to sensitive electronic components or equipment.

What are the benefits of using an anti static rubber mat?

The benefits of using an anti static mat include protection of electronic components, increased safety, improved product quality, and reduced maintenance costs. Anti static mat prevent static electricity buildup, which can damage or destroy sensitive electronic components, and reduce the risk of electrostatic discharge, which can pose a safety risk in certain environments. Additionally, using anti-static rubber sheets ensures that electronic components are not damaged during manufacturing, which improves product quality and reduces waste. Finally, anti-static rubber sheets reduce the need for maintenance and repairs caused by electrostatic discharge damage.

What applications are ESD rubber mat used for?

Anti-static rubber mats are commonly used in a variety of applications, including electronic manufacturing, cleanrooms, flooring, and packaging. They are used to line workstations, tables, and floors to prevent static electricity buildup and protect sensitive electronic components during manufacturing. They can also be used as flooring in areas where static electricity poses a risk, such as in computer rooms, laboratories, and hospitals. Additionally, anti-static rubber sheets can be used as packaging materials to protect electronic components during shipping and handling.

How do I select the right anti static mat for my application?

The selection of the right anti static mat for your application will depend on factors such as the industry, application, and the specific requirements of your business. It is important to consider the conductivity requirements, chemical resistance, and durability of the material, as well as any specific application requirements such as thickness, size, and color. Consulting with a professional in the industry or contacting the manufacturer of the product can help ensure that you select the right anti-static rubber sheet for your specific needs.

What is the difference between ESD rubber mat and static dissipative rubber sheet?

The main difference between ESD rubber mat and static dissipative rubber sheet is that anti-static rubber sheet prevents static electricity buildup, while static dissipative rubber sheet helps to dissipate static charges that are already present. Anti-static rubber sheet contains conductive particles or fibers within the rubber material, which help to dissipate static charges on the surface of the rubber, while static dissipative rubber sheet is designed to reduce static charges by providing a conductive path to ground.

Can anti-static rubber sheet be used for flooring?

Yes, anti-static rubber sheet can be used for flooring in areas where static electricity poses a risk, such as in computer rooms, laboratories, and hospitals. Anti-static rubber flooring can help to prevent static electricity buildup and protect sensitive electronic components or equipment from damage.

How is anti-static rubber sheet manufactured?

Anti-static rubber sheet is manufactured using a variety of methods, including compression molding, injection molding, and extrusion. The rubber material is typically infused with conductive particles or fibers, which help to dissipate static charges on the surface of the rubber. The manufacturing process may also involve the addition of other materials, such as colorants or additives, to improve the durability and performance of the material.

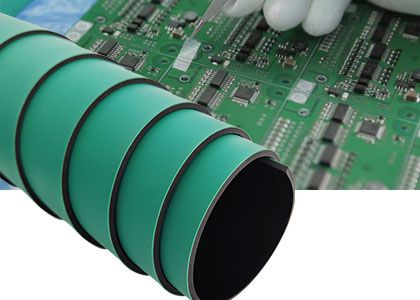

We are producing:

- Gravity:1.5g/cm³

- Color:Green+ black / Blue +black / Black +black /gray+Black / Silver+Black

- Hardness:65±5 Shore A

- Thickness:2mm-100mm Width:1m-2m Length:5m /10m /15m /20m

To maintain and clean anti-static rubber sheet, it is important to follow the manufacturer's recommendations for cleaning and maintenance. Generally, anti-static rubber sheet should be cleaned using a mild soap and water solution, and dried with a clean, lint-free cloth. Harsh chemicals or abrasive cleaners should be avoided, as they can damage the material or reduce its anti-static properties. It is also important to avoid exposing anti-static rubber sheet to extreme temperatures or high humidity, as these conditions can reduce its anti-static properties.

What is the cost of anti-static rubber sheet?

The cost of anti-static rubber sheet will depend on a variety of factors, including the size, thickness, and quality of the material, as well as the specific requirements of your application. Generally, anti-static rubber sheet is more expensive than non-anti-static rubber sheet due to the addition of conductive particles or fibers within the material. It is important to consider the long-term benefits of using anti-static rubber sheet, such as improved product quality, reduced maintenance costs, and increased safety, when evaluating the cost of the material.

Since we have not released the detailed products of ESD rubber mat at present, if you are looking for suppliers or factories for mass purchase, you can find our business personnel to contact, and she will provide you with detailed specifications and quotations

Kathery Cui:

Whatsapp: 008615222735180

P.H: +8615222735180

Email: info@chn-rubber.com

Wechat: 008615222735180

Address: Business center industry parking , yan'an Road , Nankai district, Tianjin , China.

Tianjin China Rubber Co., Ltd